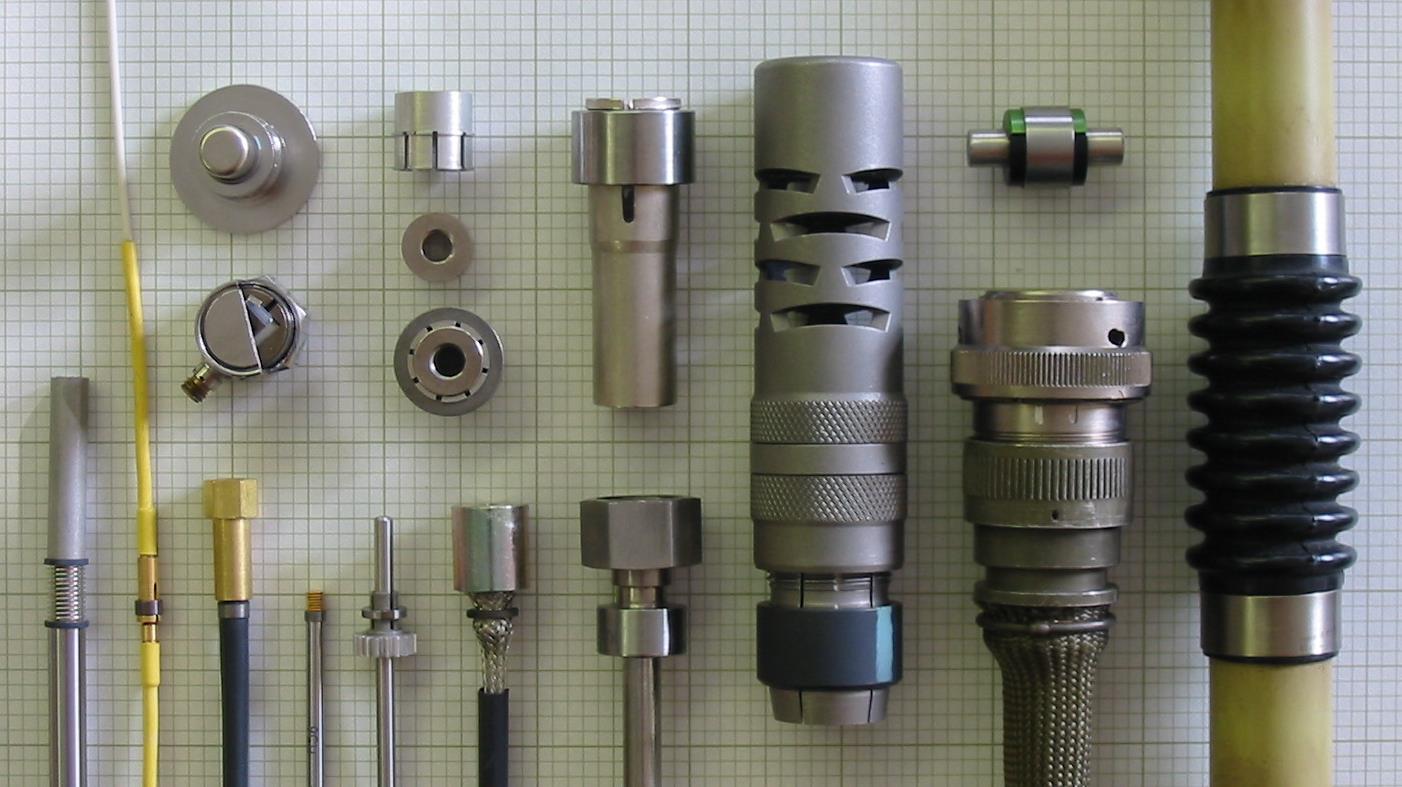

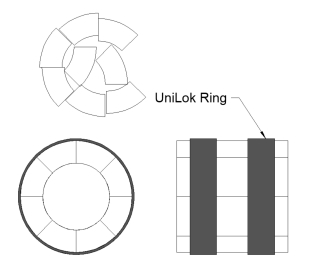

Braid Terminations

Terminate metallic EMI shielding braids

as well as Kevlar®, Tyvek®, steel and fiberglass mechanical braids.

Use for small diameter electrical cables, fiber optic cables, overbraided

hoses, and towed array strength members. UniLok is especially

advantageous for applications with severe vibration, thermal cycling or

high temperatures that lead to rapid deterioration of other braid termination

types.

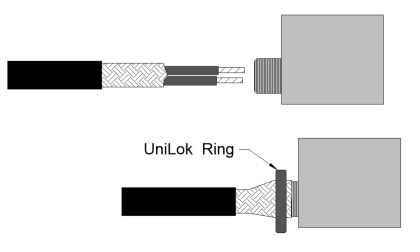

The UniLok ring produces a very high contact pressure between the braid

and connector such that a "gas tight seal" is created. This

means that oxygen is excluded from the contact area so the contact surfaces

will not oxidize over time, whch would otherwise lead to increasing electrical

contact resistance.

top

site navigation

|

|

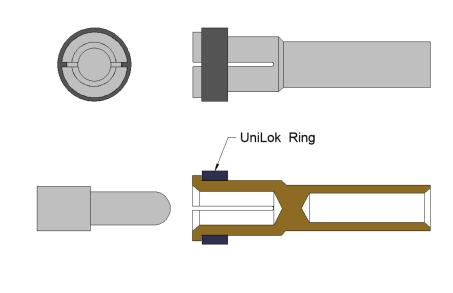

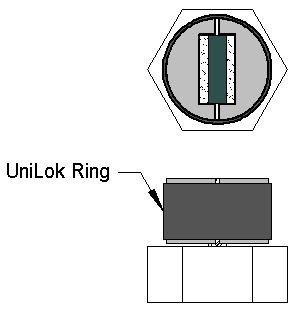

Electrical

Connectors

Zero insertion force combined with extreme

retention strength and vibration resistance. The exceptionally high

contact closure force applied by the shape memory ring produces a gas-tight

seal between contact surfaces, resulting in a stable, low-resistance connection.

Use for munitions, missiles, high amperage buss connections and bulkhead

feedthroughs. The connector is de-mated by cooling with either liquid

nitrogen or HFC spray refrigerant, depending on the alloy chosen.

top

site navigation |

|

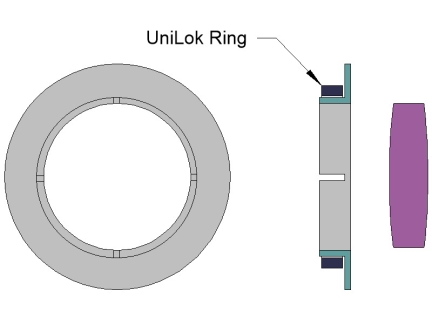

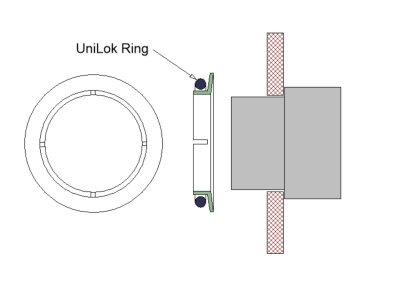

Lens and Window Mounts

UniLok fastener rings apply even pressure

to mount delicate lenses in holders. When a sealed mount is required,

the ring compresses a non-slotted tubular fitting onto the lens or window.

A soft metal plating may be applied to the fitting to enhance sealing.

Use for sapphire, germanium, ferrite and calcium fluoride lenses and windows.

top

site navigation |

|

Magnet Assemblies

Bind magnet assemblies where extreme

temperatures, rpm or shock loading render other assembly techniques inadequate.

UniLok shape memory rings offer over

10 times the motion of conventional thermal shrink fits. This allows looser

tolerances on mating parts and results in the large interference strains

needed to achieve consistent clamping pressure. Installation time for

shrink fits can be quite limited, while heat-to-recover UniLok rings allow

unlimited time for positioning components prior to shrinkage.

top

site navigation |

|

Accelerometer

Assembly

Clamp mass elements and piezoelectric

material against the center post of shear type accelerometers. UniLok

shrink rings provide easy assembly, consistent performance, and insensitivity

to temperature extremes.

top

site navigation |

|

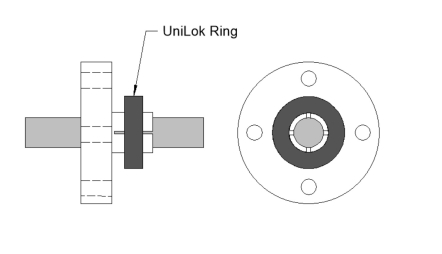

Shaft Clamps

Reliable clamping in a lightweight,

compact, balanced package. No threaded fasteners to vibrate loose. Much

smaller size than mechanical shaft collars of equivalent holding strength.

Precise axial and angular positioning can be achieved since heat is used

to set the clamp, rather than applying an external torque which can cause

unwanted movement. Use for rotary power transmission, instrument assembly

and torsion bars. We make UniLok shrink collars for small diameter shafts

where other collar styles are unavailable.

top

site navigation |

|

Axial Preload

Allows a precise preload force to be

applied and then locked in. Avoids the fines generation which occurs

when press fitting. Use for bearings, disk mounting, and other axially

preloaded assemblies.

top

site navigation |

|

Preload of Threaded Fasteners

UniLok memory metal rings installed

as washers expand in length as they shrink in diameter, applying controlled

preload.

top

site navigation |

|

Locking Nuts

Heat shrink rings provide positive

locking of critical threaded joints. No interference with torque/tension

relationship during tightening.

top

site navigation |

|

Hermetic Seal

Shape memory alloy seal rings swage

thin-walled metal cups and tubes onto headers to seal hermetic assemblies.

The ring drives the can onto the teeth and holds it there for the life

of the joint. Use in the packaging of gyroscopes, sensors, fuses, and

other electro/optical/mechanical packages.

top

site navigation |

|

Tube

Joints

UniLok heat shrinkable rings offer seamless

clamping pressure that can be controlled to terminate anything from thin

elastomeric tubing to heavy wall steel pipe.

In the joint pictured, two SMA rings

swage the tubes onto a fitting with circumferential sealing lands, teeth,

on its outside surface. This geometry is used for deformable composite

tubing and thin wall metallic tubing such as aluminum conduit and ducting.

Generally, the fitting is a harder material

than the tube. The teeth bite into the tube, locally flowing the

tube material to create the seal and providing a mechanical interlock

for burst, tensile and bending strength.

top

site navigation |

|

Swaged Fitting Tube

Joint

The

UniLok ring compresses a fitting onto the outside of a tube. Teeth

on the inside of the fitting barrel are driven into the surface of the

tube. This design is applicable to most metallic pipe and tube except

for very thin wall (small t/d). It is also used for attaching metal

fittings to rigid composite tube and polymeric fittings to thin wall metal

tube.

Typically the fitting material is chosen

to be of similar hardness to the tube. However, polymeric fittings

are generally of lower hardness than the tubing. In this case sealing

is achieved by flattening of the teeth against the tube.

top

site navigation |

|

Hose

Termination

The UniLok ring compresses elastomeric

or plastic tubing onto a fitting

with closely spaced sealing lands. Potential applications include

sonar towed arrays, geophysical streamers, high temperature Viton®

sleeving, Teflon® tubing, and wiring harness boots for high temperature

applications. Generally UniLok rings are advantageous for high strength

or thin walled tubing where crimp rings and hose clamps fail due to insufficient

retained clamping force or non-uniform clamping pressure. Thin UniLok

bands can be used where the closure mechanism on other bands creates problems

with snagging, space constraints or, in towed arrays, noise generation.

top

site navigation

|

|

Rod and Cylinder Mechanical Joints

Many designs are possible depending

on the requirements and materials involved. One cylinder may overlap

the other with a UniLok ring compressing the outer cylinder onto the inner

cylinder. In other cases, each end of a coupling sleeve is compressed

onto a cylinder end by a ring. The joint may hold by simple friction of

smooth surfaces pressed together, or teeth can be machined on one surface

to dig into the other. The outer cylinder or sleeve is normally

slotted to reduce the ring clamping force required. Slots offer

the additional benefit in toothed designs by introducing circumferential

interruptions in the teeth that increase torque strength. Use for

telescoping structures, metal to ceramic joints, etc.

Large tubular structures can be joined with simple marmon clamps locked

in place by shape memory alloy rings.

top

site navigation

|

High strength coupling with zero

axial and angular play.

Interlocking crenellated cylinders,

high torque strength

|

Tamperproof Fastening

UniLok fastener rings are ideal for

security and general tamper proofing applications, offering no conventional

means of dis-assembly. Removal requires cutting with powered abrasive

tools or cooling with liquid nitrogen. Rings made with our nitinol

Alloy D can be removed with "freeze spray" or CO2. Use for field

assembly of security hardware, tamperproof closures for instruments, etc..

top

site navigation

|

|

Blind

Assembly

Since UniLok rings are actuated by temperature,

they can be installed in remote or inaccessible locations. Heating can

be accomplished by placing the assembly in an oven, ducting hot air or

oil to the ring, induction heating or by conduction from an electric heater

element.

top

site navigation |

|