I n t r i n s i c D e v i c e s I n c o r p o r a t e d

I n t r i

n s i c D e v i c e s I n c o r p o r a t e d

Active

Fasteners

In most cases

our products are used as permanent or semi-permanent fasteners. The alloy is

chosen such that the fastener will exert clamping force over the entire ambient

temperature range the assembly will experience. For

disassembly, the fastener is brought below normal ambient temperature using

a coolant. For alloy H, liquid nitrogen is used and for Alloy D, HFC spray coolant,

carbon dioxide or liquid nitrogen is used.

UniLok rings and Intrinsic's other products can also be used to perform fastening or unfastening functions in response to changes in ambient temperature. For example, a UniLok ring can clamp and immobilize a mechanism when the device is overheated in a fire. Alternately, a shape memory element can actuate a release mechanism when exposed to elevated temperature. This might be used to deploy an instrument or to breach a pressure vessel to render it non-propulsive or non-explosive. A shape memory fastener can also hold an object securely at normal ambient temperatures and release it when deployed to a colder environment. Illustrations of various applications are given below.

Electrically controlled, rather than ambient temperature sensing, actuator mechanisms are also possible. In this case power is applied to an electric heater to bring the shape memory element to its recovery temperature.

Rod Immobilizer Here a nitinol ring shrinks when heated above a particular temperature, gripping a rod to immobilize it. Typically Alloy G or N rings are used for this type of application, giving nominal lock temperatures of 105°C or 130°C respectively. This arrangement is a simple way to add fire safety functions to a device.

|

|

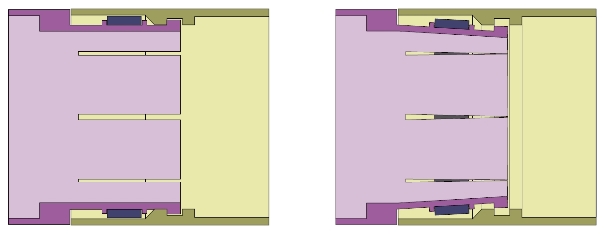

Plug Release In this configuration, an SMA ring is used as a self releasing snap ring. When the device is heated above normal ambient temperature, the ring shrinks, disengaging from the outer shoulder. This sort of release mechanism can be used for fire suppression systems and insensitive munitions slow cook-off venting. Nominal release temperatures of 105°C or 130°C are typically specified. The release temperature depends on the load and the design of mating components as well as on the shape memory ring. The tolerance on release temperature could be as low as ±5°C with a favorable design. A tolerance of ±10°C to ±15°C is more typical. See US patent 7051511, "Method and arrangement for preventing encased explosives being caused to explode by an external fire". This patent expired on May 30, 2014. |

|

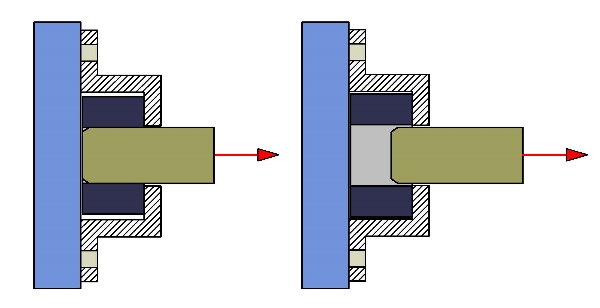

Collet Style Release An alternate release mechanism is pictured here. The two cylinders are joined by a snap fit. When exposed to elevated temperature, the memory metal actuator ring compresses the collet, disengaging its fingers from the groove in the outer cylinder. See US patent

6,321,656 "Thermally Actuated Release Mechanism" which documents

a concept for rocket motor venting during slow cook off.

|

|

Unloading Bolted Joints Shape memory washers can be produced to expand in thickness when heated and contract in thickness when cooled. If such a washer is incorporated into a bolted joint, it provides a means of tightening and loosening the joint in response to temperature. One potential use is as a "thermal conduction switch" to provide a good thermal path between a heat source and a radiator panel while heat is being generated. When the heat source is inactive, the heat flow path is decoupled to prevent excess cooling of the heat source. See the description of work done at JPL in NASA Tech Briefs "Shape-Memory-Alloy Thermal-Conduction Switches". In another instance, this concept was used as a way of deconstraining a structure once deployed into the cold of space. The Tropospheric Emission Spectrometer launched aboard NASA's Aura spacecraft on July 15, 2004 contained several of these shape memory washer assemblies. Read the NASA Technical Support Package, "An Autonomous Passive Optics Bench Release/Reclamp Device Using Shaped Memory Alloys". |

|

Bolt Release An expanded martensitic ring is press fit into a bushing. The resulting compressive stress in the martensitic ring is low, but consistent. The retention strength comes from simple friction. An Alloy G ring with an OD of 0.2", a wall thickness of 0.022" and a length of 0.31" holds tensile loads greater than 250 pounds. The joint is released by powering a film heater wrapped around the bushing. This release mechanism is extremely simple, reliable, small and lightweight. It offers a no-shock release. See the work done on this at the Naval Postgraduate School. |

|

Pin Release A NiTi ring serves as a passive release mechanism for spacecraft hardware such as solar panels. The ring grips while warm on Earth and in the launch vehicle. When the satellite is deployed into the cold of space, the ring relaxes, providing a zero-shock separation. The release delay can be adjusted by the selection of alloy transfomation temperature and thermal insulation. Compare this to a more conventional approach. Launch Tie-Down and Release Mechanism for CubeSat Spacecraft. |

|

Copyright

2003 Intrinsic Devices, Inc. All rights reserved.